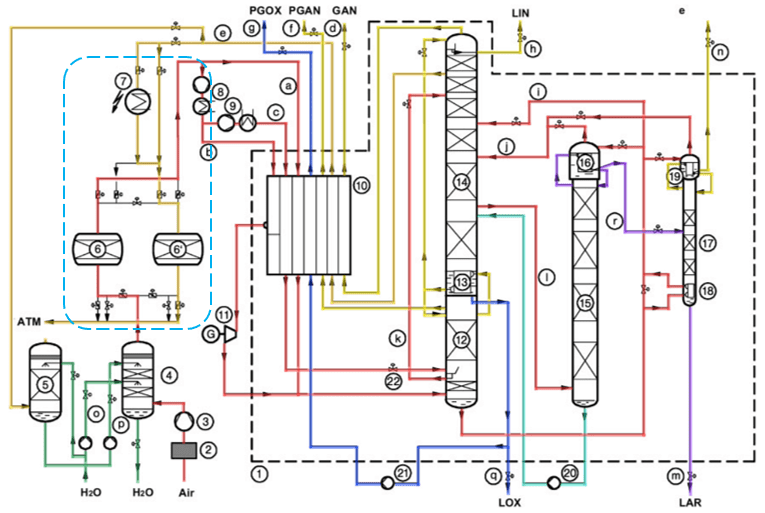

After a pre-cooling process, the atmospheric air still contains some impurities, such as carbon dioxide, hydrocarbons, moisture, etc. These impurities must be reduced to a certain value so that they will not bring any problems to the subsequent cooling and separation processes.

Carbon dioxide could cause dry ice to block inside the main heat exchanger (10), while moisture could cause solid ice to block. On the other hand, hydrocarbons could bring a safety risk, especially in the sump of the upper column (14). Typically, carbon dioxide and moisture are reduced to ~1 ppm and ~2 ppm, respectively.

Warm Section (Purification)

(Heinz-Wolfgang Häring, 2008)

The purification process happens in a pairwise adsorber vessel (6 or 6’). Adsorption is the adhesion of molecules from a gas to a solid surface. Atmospheric air passes through a double-layer adsorbent in a vessel. The activated alumina functions to adsorb the moisture impurity, while the molecular sieve functions to adsorb the carbon dioxide and hydrocarbons impurities.

A typical adsorption cycle time is between ~4 – ~8 hours. That means, a vessel (6) undergoes an adsorption process for a certain duration, while another vessel (6’) undergoes a regeneration process for a certain duration. A regeneration process consists of the following steps:

- Depressurizing with the help of solenoid valves.

- Heating by waste nitrogen gas (e) from the cold box (1).

- Cooling by waste nitrogen gas (e) from the cold box (1).

- Pressurizing with the help of solenoid valves.

- Switching with the help of solenoid valves.

An electric heater (7) will be in operation during the heating step, while the residual gas and impurities are vented through a silencer to the atmosphere (ATM).

Reference

Heinz-Wolfgang Häring. (2008). Industrial Gases Processing. John Wiley & Sons.

Leave a comment